Omtech Food Engineering is a producer, exporter, and supplier of conveyor and modular belt turn-key solutions. It insists on providing top-notch machinery with a high degree of containment for innovations and supporting a variety of industries, including the automotive, rubber, and food industries, through conveyor belts.

A stainless steel belt conveyor is a type of conveyor system that utilizes a stainless steel belt to transport materials or products from one point to another within a production or industrial facility. Stainless steel is chosen for its corrosion resistance, durability, and hygienic properties, making it suitable for applications in various industries, including food processing, pharmaceuticals, and manufacturing. Here are key features and considerations associated with stainless steel belt conveyors:

Applications:

Stainless steel belt conveyors are commonly used in industries that require a high level of cleanliness and sanitary conditions, such as food processing, pharmaceuticals, and electronics manufacturing. They are also suitable for applications where products may be sensitive to contamination.

Belt Types:

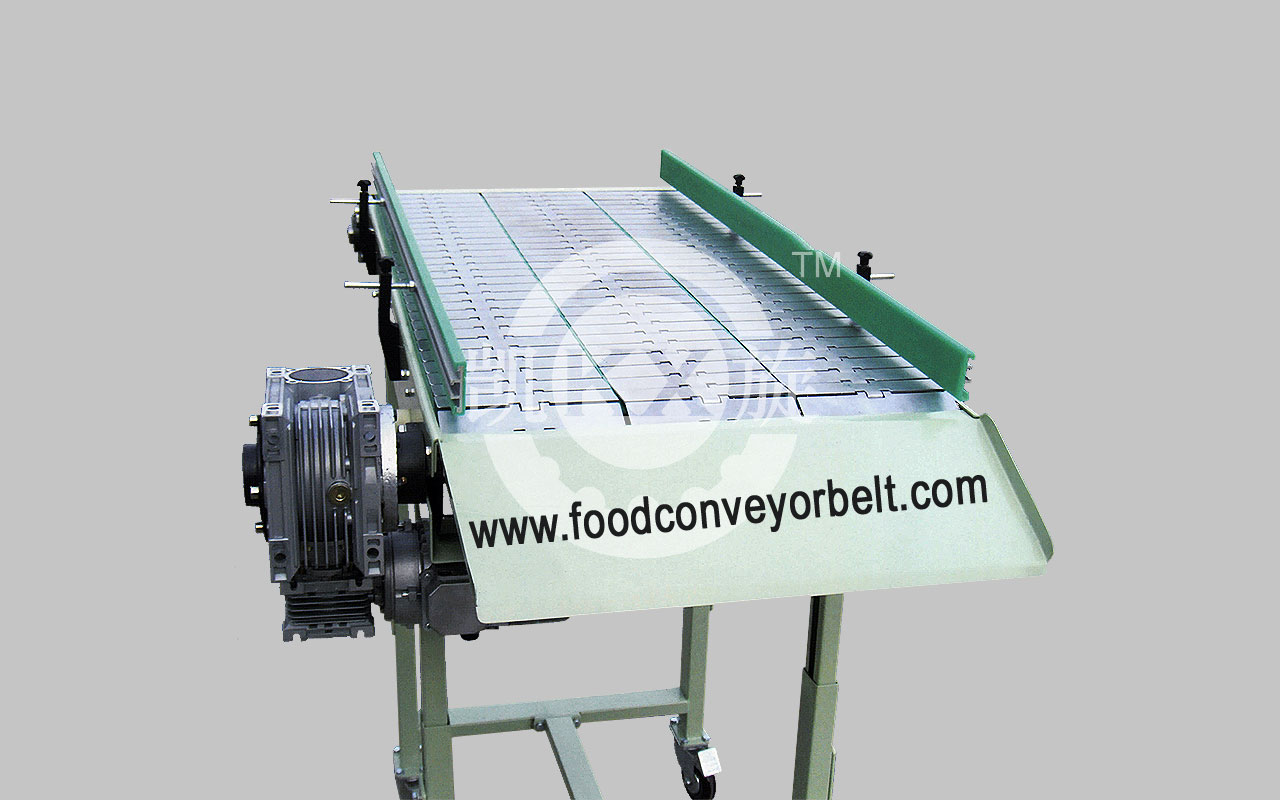

Depending on the application, different types of stainless steel belts conveyor may be used. These can include flat wire belts, balanced weave belts, and other designs suitable for the specific material handling needs.

Adjustable Height and Incline:

Some stainless steel belt conveyors are designed with adjustable height and incline features, providing flexibility in the layout and configuration of the conveyor system to meet the needs of different production processes.

Modular Construction:

Many stainless steel belt conveyors are built with a modular construction, allowing for easy assembly, disassembly, and modification. This modular design facilitates quick changes to the conveyor system as production needs evolve.

Specifications for stainless steel conveyors or devices are determined by factors including product processing that involves chemicals or corrosives, sanitary standards for food and medicines, and washdown environments. Concerns about bacterial growth and moisture content influence the choice of coatings.

Stainless steel belt conveyors play a critical role in industries where sanitation, durability, and corrosion resistance are paramount. The choice of a stainless steel conveyor is often driven by the specific requirements of the materials being conveyed and the environmental conditions in which the conveyor operates.